Flüssiggasverdampfer, Gasverdampfer

Gasverdampfer Flüssiggas - KBV

Gasverdampfer Flüssiggas - KBVKapazität: LPG 500 - 2000 kg/h

Art: Indirekte Beheizung mit einem Gasbrenner

Elektrische Energie: 0,5 – 1,5 kWh

Elektrische Parameter: 220V, 1P, 50Hz

Leistung des Brenners: 120 - 350 kWh

Magnetventil für den LPG-Eingang mit CE (ATEX)

Elektrischer Flüssiggasverdampfer - KEV-SR

Elektrischer Flüssiggasverdampfer - KEV-SRKapazität: LPG 500 - LPG 50 - 1200 kg/h

Art: Elektrisch beheizt und trockenartig

Elektrische Energie: 220V 1P(3P) 50(60)Hz / 380V 3P 50(60)Hz

Elektroheizung: 4,5 - 180 kWh

Magnetventil für den LPG-Eingang mit CE (ATEX)

Elektrischer Trocken-LPG-Verdampfer - KDV

Elektrischer Trocken-LPG-Verdampfer - KDVKapazität: LPG 30 - 100 kg/h

Art: Elektrisch beheizt und trockenartig

Elektrische Energie: 220V 1P(3P) 50(60)Hz / 380V 3P 50(60)Hz

Elektroheizung: 4,5 - 15 kWh

Magnetventil für den LPG-Eingang mit CE (ATEX)

Wasser-LPG-Verdampfer - KWV

Wasser-LPG-Verdampfer - KWVKapazität: 100 – 2000 kg/h

Art: Heißwasser-Umlaufsystem

Durchflussmenge von heißem Wasser42 - 840 Liter/Minute

Elektrische Parameter:220V, 1P, 50Hz

Warmwasserkesselkapazität: 15 000 – 300 000 kcal/h

Kein elektrischer Strom und keine Steuerung

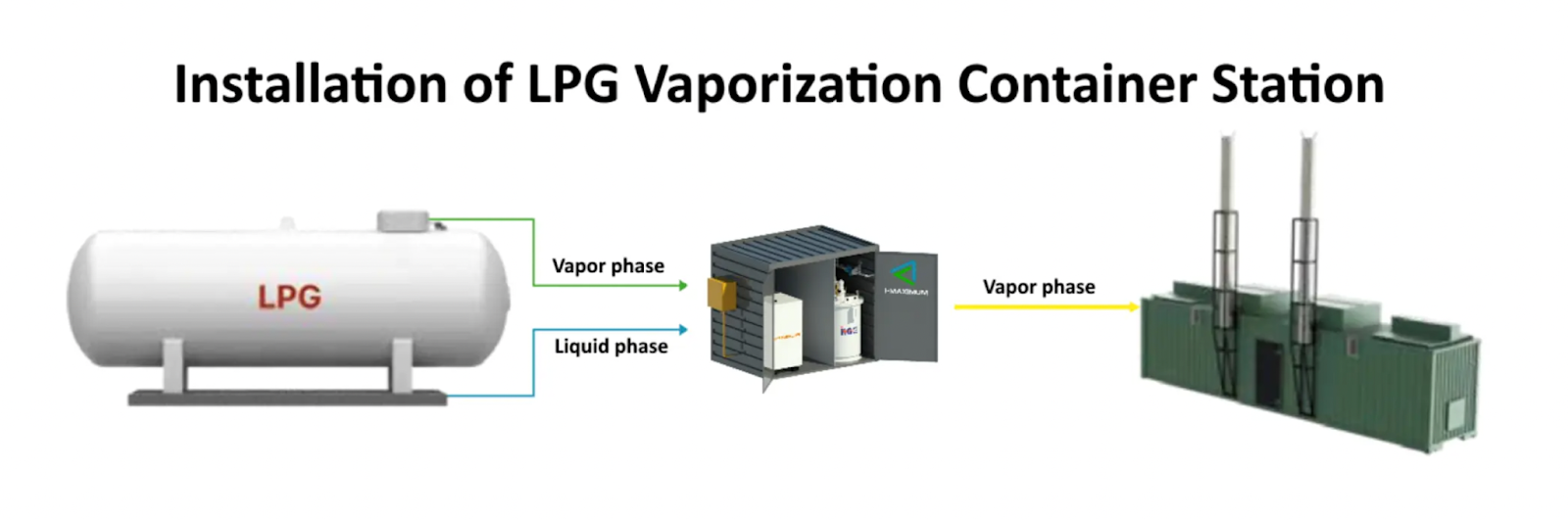

Containerisierte LPG-Verdampfungsstation

Containerisierte LPG-VerdampfungsstationKapazität: LPG 200 – 1000 kg/h

Heißwasser-Umlaufsystem mit Kessel in einem Container

Heißwasser-Durchflussmenge: 84 - 420 Liter/Minute

Heißwasserkesselkapazität: 30.000 - 150.000 kcal/h

I-Maximum auf Ausstellungen und Konferenzen

Wann verwenden wir SNG (Propan-Luft)?

Flüssiggasverdampfer

Unter vielen Arten von Gasen ist Propan das gefragteste und wird immer beliebter als primäre Energiequelle. Die Gründe für seine Beliebtheit liegen in seinem großen Vorkommen, seiner Kosteneffizienz und seinem umweltverträglichen Profil im Vergleich zu anderen Arten von Brennstoffen. Die einfache Handhabung in Kombination mit diesen Vorteilen hat Propan zur einzigen Alternative gemacht, wenn es um Brennstoff für die Beheizung von Unterkünften, landwirtschaftliche Grundlasten und Anlagen geht. Darüber hinaus wird Propan als Not- und Zusatzbrennstoff für industrielle Heizprozesse und die Stromerzeugung eingesetzt, insbesondere in abgelegenen Gebieten, die Schwierigkeiten beim Zugang zu Gasleitungen haben. Die Implementierung von Gas als Brennstoff für all diese Sektoren und Unternehmen erfordert ein tiefgreifendes Verständnis der eigentlichen Essenz eines Verdampfers, der Spezifikationen des LPG-Systems, des Designs des LPG-Verdampfers, der Natur der Verdampfung und des Arbeitsprinzips des LPG-Verdampfers. Darüber hinaus erfordert es das Wissen über viele damit verbundene Aspekte, die die LPG-Verdampfungsrate, das Niveau der Umgebungslagertemperatur, den Füllpunkt und die Größe der LPG-Speichertanks, den geeigneten Lagertankdruck, die Rate des Kraftstoffverbrauchs für unterstützte Geräte, mögliche Sicherheitsfragen und so weiter umfassen.

Die Implementierung von Gas als Brennstoff für all diese Sektoren und Unternehmen erfordert ein tiefgreifendes Verständnis der eigentlichen Essenz eines Verdampfers, der Spezifikationen des LPG-Systems, des Designs des LPG-Verdampfers, der Natur der Verdampfung und des Arbeitsprinzips des LPG-Verdampfers. Darüber hinaus erfordert es das Wissen über viele damit verbundene Aspekte, die die LPG-Verdampfungsrate, das Niveau der Umgebungslagertemperatur, den Füllpunkt und die Größe der LPG-Speichertanks, den geeigneten Lagertankdruck, die Rate des Kraftstoffverbrauchs für unterstützte Geräte, mögliche Sicherheitsfragen und so weiter umfassen.

Vorteile von Flüssiggas (LPG)

Unter den Bedingungen von Standardtemperatur und -druck bleibt Propan in Form eines gasförmigen Brennstoffs. Dennoch wird Gas unter messbarem Druck verflüssigt, um Flüssiggas (LPG) für eine effiziente Handhabung und Lagerung von Propan herzustellen. Im flüssigen Zustand kann LPG bequem und kostengünstig in Zylindern und Lagertanks versandt und gelagert werden.

Jedes gasverbrauchende Gerät (Prozessbrenner, Kessel, Heizgerät) kann Flüssiggas (LPG) verbrauchen, vorausgesetzt, das Gas befindet sich im gasförmigen Zustand. Sobald das verflüssigte Gas den Vorgang des Verdampfens durchläuft und in seinen natürlichen Zustand zurückkehrt, wird es wieder zu Dampf.

Glücklicherweise erfolgt der Propan-Verdampfungsprozess bei Umgebungstemperaturen. Anders ausgedrückt reicht es in den meisten Fällen aus, Propan einfach aus seinem Druckbehälter freizusetzen, um einen Gasstrom zu erzeugen, der im Wesentlichen für gewerbliche und häusliche Gasanwendungen ausreicht.

Die Gründe, Vaporizer zu benutzen

Um einen stabilen und zuverlässigen Betrieb Ihrer gasbetriebenen Geräte zu gewährleisten, muss das Volumen an Propan, das Ihr Gasgerät aus einem Speicherbehälter entnimmt, mit der Vergasungsrate übereinstimmen. Die Geschwindigkeit der natürlichen Verdampfung pro bestimmtem Zeitraum hat jedoch ihre Grenzen aufgrund der Umgebungstemperatur und der Größe des Lagerbehälters (einschließlich des Füllstands des Tanks).

Jede Temperatur, die das Umgebungsniveau übersteigt, wird eine schnellere Gasbildung bewirken, kombiniert mit einem intensiveren Dampfdruck. Ebenso wird ein sperrigerer, vollerer Lagerbehälter jeweils eine größere Verdampfungskapazität verursachen.

Gleichzeitig erzeugen niedrige Temperaturen oder kleine und halbleere Lagertanks einen niedrigeren Dampfdruck, der möglicherweise nicht ausreicht.

Wenn der Taupunkt der Umgebungsluft höher wird als die Temperatur der Flüssigkeit im Tank, wird sich Frost am unteren Teil des Lagertanks bilden und sich bis zur Höhe der Flüssigkeit ausbreiten. Wenn das Lagervolumen mit Eis bedeckt ist, ist dies ein deutlicher Hinweis darauf, dass Ihr Behälter einfach nicht groß genug für die erforderliche Verdampfungskapazität ist.

Jeder Teil eines Geräts, das Propan verbraucht, benötigt eine bestimmte Menge Dampf, um ordnungsgemäß zu funktionieren. Natürliche Verdampfung reicht beispielsweise nicht für schwere Industriegeräte aus, die im Vergleich zu Wohngeräten größere Gasportionen pro bestimmten Zeitraum verbrauchen.

Verdampfer sind dazu gedacht, große Mengen von Flüssiggas (LPG) aufzunehmen und in verdampftes Gas mit festgelegtem Druck und Durchflussmenge umzuwandeln, die von Hunderten von Litern pro Stunde bis zu Tausenden von Litern pro Stunde reicht. Das Volumen der zugeführten Wärme an das LPG beeinflusst die Verdampfungsrate, wodurch der richtige Flüssiggasverdampfer eine konstante Lieferung von Propan gemäß Bedarf gewährleistet.

LP-Verdampferauswahl

Alle Verdampfer wurden entwickelt, um zwei Funktionen auszuführen:

Um Gasdampf in höherer Rate zu erzeugen, als es ein Propantank bieten kann.

Um synthetisches Erdgas (SNG) als direkte Alternative zu Erdgas zu erzeugen.

Des Weiteren werden wir die Arten von Verdampfern auf dem Markt für Flüssiggasverdampfer überprüfen, deren Leistungsfähigkeit und für welche Ausrüstungstypen jeder Typ am relevantesten ist.

LPG-Verdampfer-Typen

Indirekter befeuerter Verdampfer - ohne direktes Feuer Die LPG-Gasverdampfer KBV sind völlig anders als direkt befeuerte Verdampfer. Indirekt gasbefeuerte Verdampfer sind die beste Lösung für industrielle und landwirtschaftliche Unternehmen mit begrenzter Stromversorgung, die mit LPG betrieben werden. Das Funktionsprinzip der KBV Gas-LPG-Verdampfer besteht in der indirekten Erwärmung (durch ein Wasserbad) des flüssigen Anteils von Flüssiggas mit einem Gasbrenner mit einer geschlossenen Brennkammer, wodurch das flüssige Propan-LPG in eine gasförmige Phase verdampft. Der Hauptvorteil der indirekten Gasverdampfer KBV (kbv gasbefeuerte Verdampfer) liegt in der Sicherheit und Zuverlässigkeit aufgrund des Fehlens einer direkten Gasfeuerung und der Energieeffizienz aufgrund des Fehlens einer elektrischen Beheizung des Gaspropans.

KBV-Gasverdampfer sind am effektivsten für Gasbrenner mit einer Leistung von 5.000 kW bis 100.000 kW. Die Leistungsbereiche der KBV-Serie von Verdampfern liegen etwa zwischen 500 kg/h (22,7 MMBTU pro Stunde) und 2000 kg/h (90,1 MMBTU pro Stunde).

Wasserbad-VerdampferWasserbad-Verdampfer wurden als eine Reihe von Rohren konzipiert, durch die Propan fließt. Diese Rohre sind in einem isolierten Bad oder einem ähnlichen geschlossenen Raum eingeschlossen. Das Bad enthält HTS (Wärmeübertragungslösung), das von einer Bank von Brennern erhitzt wird, die an einem Ende der Einheit angebracht sind. Erdgas gelangt als Flüssigkeit in das Rohr und erhält Wärme von der HTS.

Durch die Aufnahme von Wärme verwandelt sich Propan in einen Dampf. Die SPS (speicherprogrammierbare Steuerung) überwacht die Verdampfungsrate, die durch die Durchflussmenge des zugeführten Gases und das Volumen der zugeführten Wärme voreingestellt ist.

Jeder Flüssiggas-Verdampfer ist für den Einsatz in Dauerbetriebsgeräten vorgesehen, die beispielsweise in Hotels, Gefängnissen, Erholungszentren oder ähnlichen betreuten Einrichtungen verwendet werden können.

Die Kapazität reicht von etwa 100 kg/h (4,5 MMBTU pro Stunde) bis zu mehr als 2000 kg/h (90,1 MMBTU pro Stunde).

Elektrischer Flüssiggas-VerdampferElektrische Verdampfer verwenden Elektrizität, um Wärme zu erzeugen, indem sie sie auf das Flüssiggas anwenden, um es in Dampf zu verwandeln. Diese Art von Verdampfer ist mit einer elektrischen Klassifizierung ausgestattet, die es ermöglicht, sie direkt neben einem Gaslagertank zu installieren. Man kann sie unter der Bedingung eines begrenzten Platzes für die Installation nützlich finden.

Die Kapazität reicht von 30 kg/h (1,36 MMBTU pro Stunde) bis 1 200 kg/h (54,54 MMBTU pro Stunde).

DampfinhalatorDampfverdampfer nutzen vor Ort verfügbares heißes Wasser, Dampf oder ein beliebiges Gas hoher Temperatur als Wärmequelle, um Flüssiggas zu verdampfen. In der Regel profitieren große Industrieanlagen, die Dampf für ihre Bedürfnisse einsetzen, von dessen Verfügbarkeit zur Verflüssigung von Flüssiggas.

Dampferzeuger werden häufig in industriellen und kommerziellen Geräten verwendet, die eine konstante übermäßige Dampfversorgung bieten.

Die Kapazität reicht von etwa 500 kg/h (18 MMBTU pro Stunde) bis zu mehr als 2000 kg/h (70,2 MMBTU pro Stunde)

SNG-VerdampferSNG (synthetisches Erdgas) Verdampfer umfassen spezielle Luftmischer, die mit Standardverdampfern verbunden sind. Ein solcher Mischer verbindet Luft mit einströmendem Propan, um den Brennwert zu senken. Auf diese Weise erhalten wir synthetisches Erdgas, das das Ergebnis der "Luft-Propan"-Kombination ist. SNG-Verdampfer ermöglichen eine nahtlose Umwandlung von Erdgas zu gemischtem Propan.

Normalerweise werden Verdampfer für synthetisches Erdgas in den gleichen Anlagen eingesetzt, die auch Erdgas verwenden.

Die Kapazität reicht von 100 kg/h (4,5 MMBTU pro Stunde) bis 1 200 kg/h (54,54 MMBTU pro Stunde).

In der Regel werden SNG-Systeme als Unterstützung für Erdgas-Systeme eingesetzt und sind nur für sporadische Nutzung erforderlich.

Darüber hinaus wurden elektrische SNG-Systeme für geringe Lastanforderungen entwickelt. Diese Systeme können in sehr engen Räumen eingesetzt werden. Normalerweise dienen sie als Notfallausrüstung. Die Kapazität solcher kleinen Systeme reicht von 5 MMBTU pro Stunde bis 28 MMBTU pro Stunde.

Was können wir für Sie tun?

Wenn Sie einen konstanten und gehebelten Betrieb Ihrer Ausrüstung sicherstellen möchten, müssen Sie den geeignetsten Verdampfer auswählen. Als exklusiver Vertreter eines der besten Hersteller von LPG-Verdampfern steht die Ingenieurgesellschaft I-Maximum hier bereit, um zu helfen. Egal, ob Sie den bisher besten Verdampfer aus unserem Standardbestand benötigen oder einen speziell nach Ihren Anforderungen entworfenen Verdampfer benötigen, sind Sie hier genau richtig!